Following the Fukushima-Daiichi nuclear disaster, the Nuclear Industry began to boost protection for earthquakes, tornadoes, hurricanes, floods, snow, ice, and extreme heat. Implementing robust strategies required additional protection for installed plant equipment. Many utilities identified the need to install additional tornado missile barriers to provide additional protection.

Design of the Tornado Missile Barriers

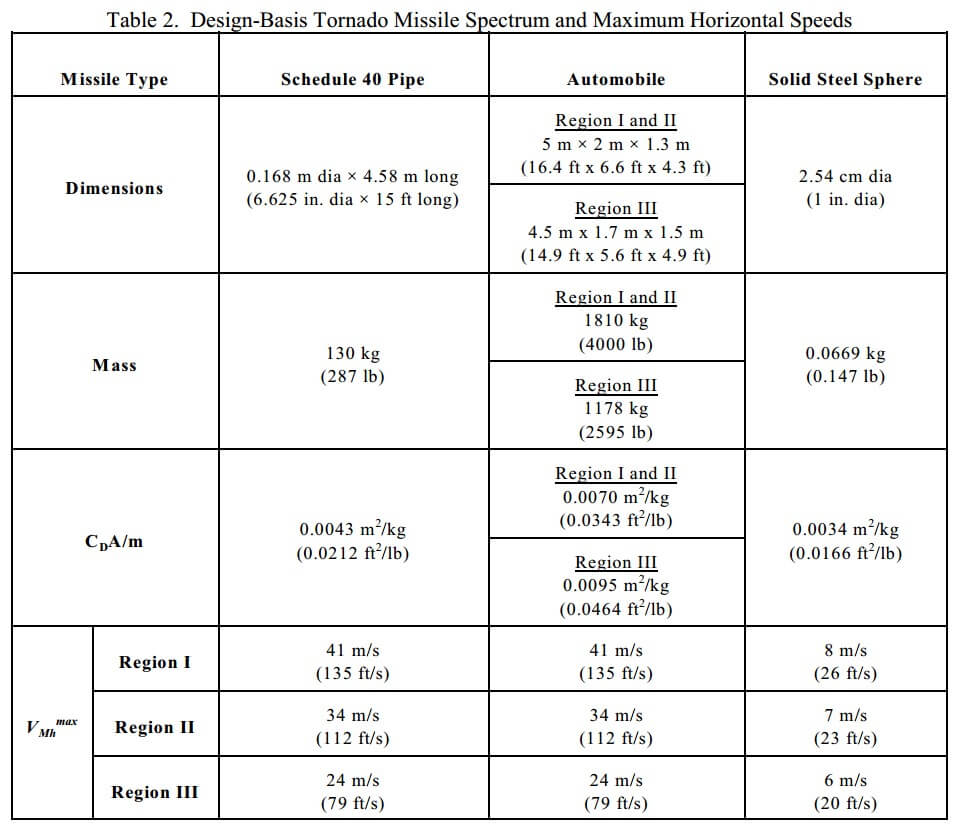

Regulatory design criteria for the new tornado missile barriers is extreme. The site was in the South, so tornadoes are not uncommon. The NRC recognizes that tornadoes can happen near the site, and they came up with the following criteria:

Design Upgrade in Tennessee

In Tennessee, a nuclear plant determined that they needed to protect a series of pipes from wind driven missiles. The pipes in need of protection were responsible for cooling the core during an accident. The regulator required that protection be enhanced, even though they were already protected from tornadoes.

Evaluating Piping Protection Alternatives for Tornado Missile BarriersAlternatives

We helped the site evaluate a few alternatives for protection of the piping system.

Fill the trench with sand

One of the alternatives considered was filling the trench with sand. The sand would help to dissipate the energy from the missile, precluding rupture of the pipes. This was also the simplest to install since the sand only needed to be dumped into the trench.

Working with site management, we found that this would create a significant burden for plant operators because there were a few valves that needed to be operated periodically inside the trench.

Install Concrete Covers

The existing trench covers were made from reinforce concrete. The concrete covers could be replaced with larger concrete covers that could simply be dropped in place.

Preliminary calculations showed that the thickness of the concrete would be much thicker than the existing panels. Again, working with site management, we learned that site personnel drive over this trench. A larger cover would require adjustments to site grading and paving that were not easy to do given other site conditions.

Install steel covers

The feasibility of using the steel covers was evaluated. We determined that steel covers could easily replace the existing concrete covers with minimal impact to the site. This was the option chosen by the site.

Designing the Barriers

Bechtel wrote BC-TOP 9A that was approved by the NRC for evaluating tornado driven debris, and the associated impacts. The Report describes in results of actual test data, and outlines a conservative method for designing tornado missile barriers.

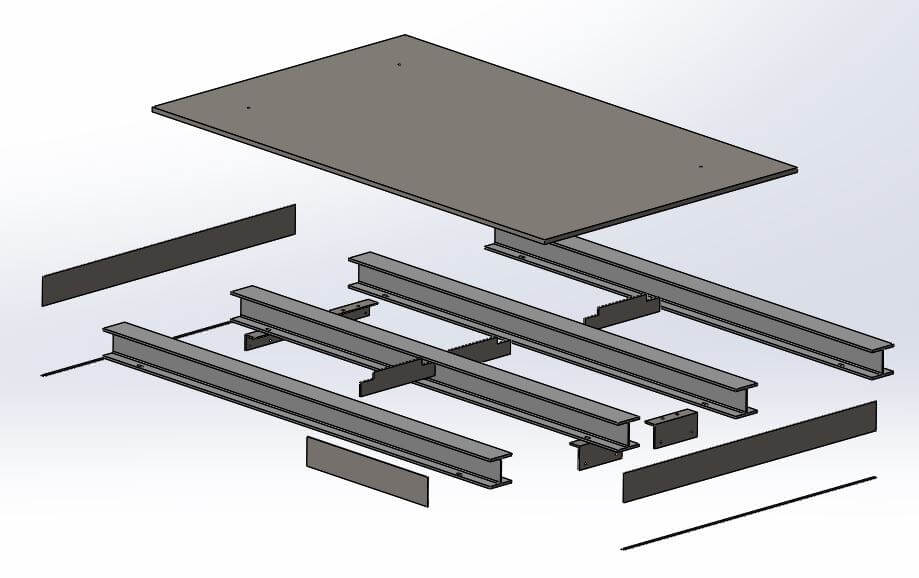

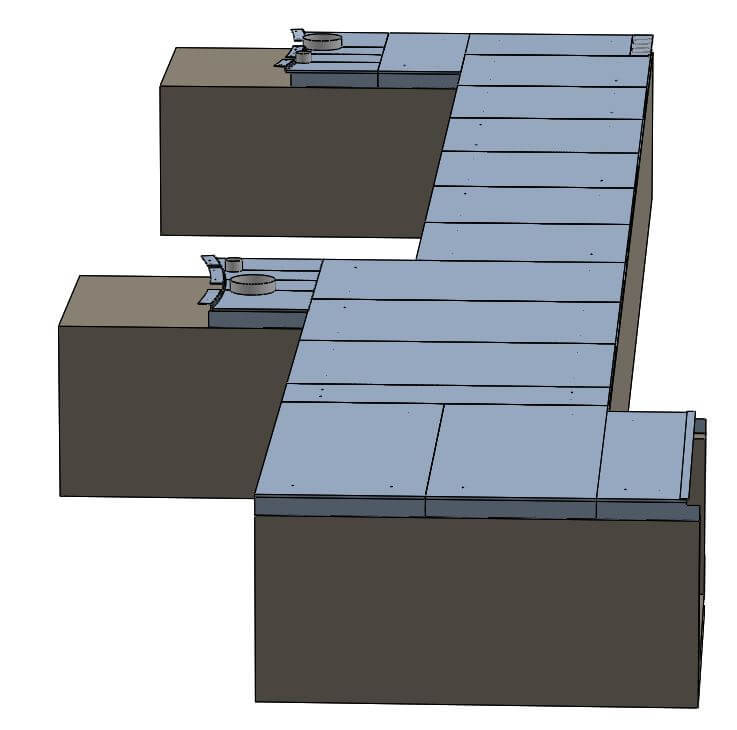

We used BC-TOP 9A in the initial sizing and design of the tornado missile barriers. The final design used 12” deep I-beams covered with 1” thick steel plate.

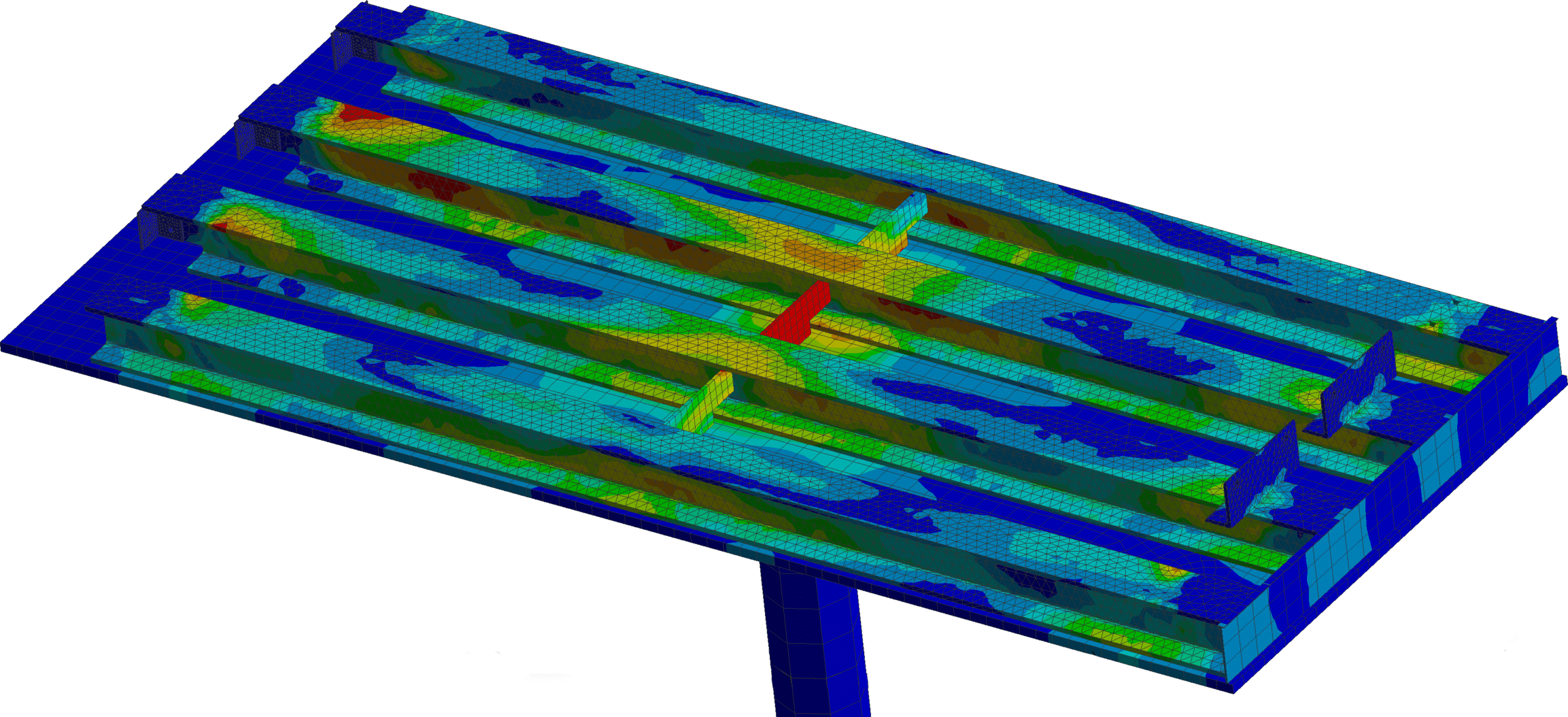

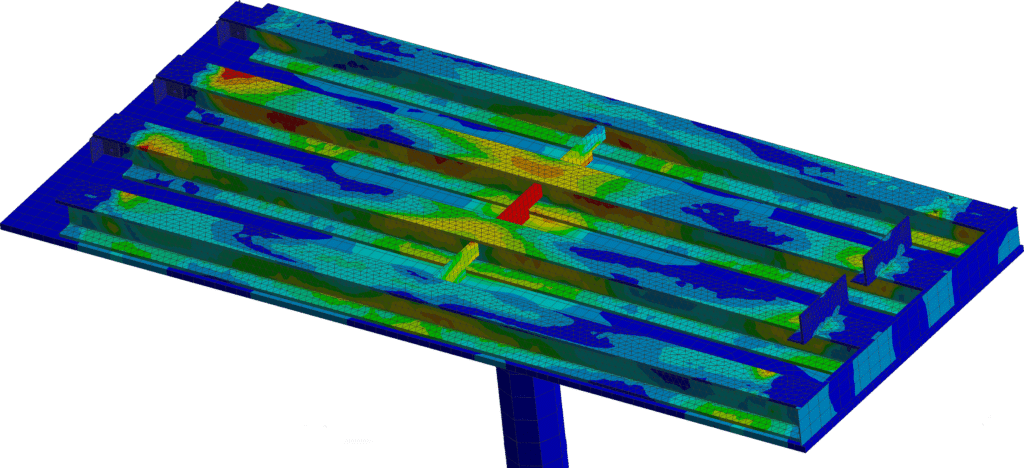

We checked the design using Finite Element Analysis, verifying that the tornado missile barriers would resist impact from wind driven debris. Based on the results of the analysis, we were able to determine that the hand methods were conservative, and acceptable.

3D Modeling

We designed the panels using 3D modeling software. We measured the existing pipe trench, including any interferences. Based on those measurements, the fabrication of the covers was able to happen off-site, saving time and money.

End Results

Off-site fabrication saved the utility a significant amount of money. Within a few days, all of the panels were in place, without the need for costly field changes.