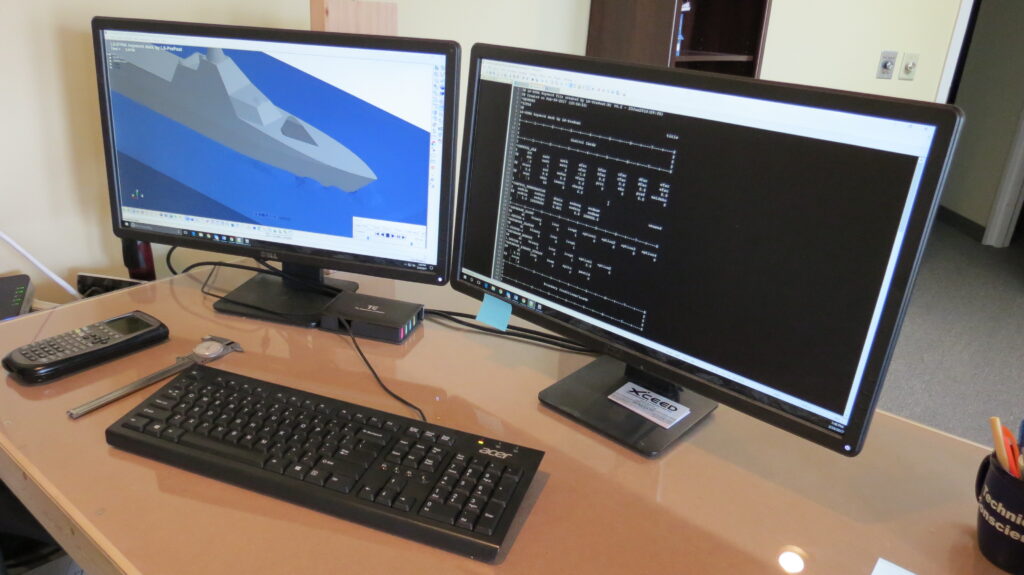

Our CFD and FEA Consultants Experience

At XCEED, our FEA consultants have over 20 years of experience using solving some of the toughest problems in the world. We started using FEA, pioneerring it’s use as a cost savings tool. On one project alone, we saved $8.8M using tools like FEA and CFD.

Our firm is one of the only licensed FEA consulting firms in the country. This means that our FEA consultants are at the top of the pack, and they undergo constant training to make sure their skills are on the cutting edge. We have a wide breadth of project experience.

Using FEA in the Design Process

Over 80% of project cost is determined in the design phase of a project. It’s extremely important to optimize the design before fabrication or production.

Our FEA consultants have worked with fabricators, manufacturers and project managers/engineers to help them save cost using FEA. We’ve found that our FEA techniques drive the cost down for the two most important aspects of a project, schedule and scope. Using FEA early in a project has allowed our FEA consultants to save an average of 27% on overall project cost. The average client using our services early in the project saved an estimated $2.2M on their project!

Scope Savings

Limiting project scope is the first step. Our team of FEA consultants has been able to evaluate existing systems, structures and components, showing that they can be either reused or otherwise credited for the project or initiative.

Schedule Savings

By cutting scope, we inherently cut schedule, but it goes beyond that. Our models are parameterized, and saved on our system forever. If your project requires a design iteration, there’s no need to go back through an arduous design process. Our FEA consultants can simply re-run models, and parameterized runs make this incredibly efficient.

Parameterization is an important part of our FEA services. Our FEA consultants can vary certain parts of the model automatically to find the most optimal solution. And because it’s automatic, it makes the design process much faster, cutting cost.

Dynamic (Transient) Analysis

Our team of FEA consultants is uniquely qualified for performing non-linear (explicit) Finite Element Analysis. We’ve simulated rapid, transient events like automobile impacts, drop tests, and blast effects for clients across the country.

Our FEA consultants use explicit code for our dynamic, non-linear analyses. This allows us to get faster, and more accurate solutions. We can also vary parameters over time like material properties, temperatures, loads and boundary conditions.

A unique aspect of our transient analysis techniques is our ability to parameterize the analysis. As FEA consultants, we can quickly setup our models for varying conditions or cases, and run through them very quickly, saving our clients time and money on simulation. The larger the project, the more can be saved by parameterization. This is also key for sensitivity studies, and failure analyses.

Our explicit FEA capabilities also extend to 2-way Fluid-Structure Interaction problems (FSI).

We’re Here to Help

If you have any questions regarding FEA, please call us at 585-340-7277. Our FEA consultants are ready to help 24 hours a day, 7 days per week. You can also email us at info@xceed-eng.com, or use the contact us form at the side of this page.