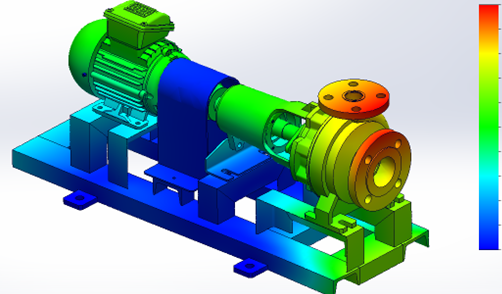

In the world of rotating equipment, particularly centrifugal pumps used in petroleum, petrochemical, and natural gas industries, reliability isn’t optional—it’s essential. That’s where Finite Element Analysis (FEA) comes into play. When performed in line with API 610 standards, FEA becomes a powerful tool to ensure that pump designs meet the mechanical integrity and reliability expectations of the most demanding applications.

What is API 610?

API 610 is the American Petroleum Institute’s standard for centrifugal pumps in hydrocarbon-processing industries. It defines stringent requirements for design, materials, and mechanical integrity. One of the core focuses of API 610 is to ensure that pumps can withstand external piping forces and moments without suffering damage or unacceptable deformation. This is where Finite Element Analysis and its integration with pipe stress analysis become essential. (For background on FEA modelling techniques, see XCEED’s article on FEA Simulation: How to Use Shell Element Results to Improve Design.)

Why Use FEA for API 610 Pumps?

FEA helps designers and engineers evaluate how a pump’s structure will respond to mechanical loads, pressure, and temperature before manufacturing. Here’s how it supports API 610 compliance:

Stress Analysis of Pump Casing and Nozzles

API 610 defines allowable nozzle load limits based on pump size and type. FEA is used to verify that, under applied piping loads, the resulting stresses in the nozzles, casing, and mounting feet remain within acceptable limits, as defined by ASME or other applicable stress criteria.

This analysis becomes even more critical when actual nozzle loads exceed the standard API 610 tabulated values—in which case FEA justification is required to demonstrate compliance.

Understanding Nozzle Loads and Stiffness: The Pump–Piping Interface

Nozzle Loads – More Than Just Numbers

Pumps don’t operate in isolation—they are part of a piping system. Pipe stress engineers calculate the forces and moments applied at the pump nozzles based on thermal expansion, dead weight, pressure thrust, and seismic or dynamic events.

If these loads are too high, they can cause:

- Casing distortion

- Shaft misalignment

- Seal or bearing failures

- Bolt overstress

- Fatigue issues over long-term operation

Stiffness Matters: Translating Loads Into Stresses

FEA not only evaluates how much load a pump can take, but also how stiff the pump is at its nozzle locations. The nozzle flexibility (or stiffness) determines how the pump reacts under pipe loads:

- A very stiff nozzle may transfer large loads into the casing, increasing stress and deflection.

- A more flexible nozzle can accommodate movement better but may affect pump alignment or structural stability.

In a well-integrated workflow, the pump manufacturer provides stiffness matrices (force vs. displacement relationships) for each nozzle. These matrices are then imported into the pipe stress analysis software (e.g., CAESAR II, AutoPIPE, ROHR2) by the piping engineer.

This iterative loop ensures that:

- The piping layout and supports are optimized to reduce load on the pump.

- The pump design is validated for those actual loads, even if they exceed API 610’s tabulated limits.

Key FEA Outputs for Nozzle Load Evaluation

- Stress plots and stress intensity maps for the casing under applied nozzle loads

- Deflection and angular rotation of the nozzle (used to assess alignment)

- Nozzle stiffness matrices (force and moment per unit displacement and rotation)

- Reaction loads at mounting feet to assess baseplate and foundation design

- Comparison of results with allowable limits from API 610 or ASME Section VIII Div 2

Tie-In with Pipe Stress Analysis: A Two-Way Process

Integrating FEA with pipe stress analysis is not a one-time pass—it’s an iterative process involving:

- Initial Piping Loads: Pipe stress engineer provides estimated loads at pump nozzles

- FEA Validation: Pump engineer uses FEA to assess pump response and potential overstress

- Stiffness Feedback: Pump engineer provides stiffness data to piping team

- Refined Analysis: Piping loads are re-calculated using more accurate boundary conditions

- Final Validation: FEA is re-run with refined loads to ensure compliance and reliability

This collaborative approach leads to a better-designed system and avoids field issues like hot alignment problems, excessive vibrations, seal or bearing failures.

Conclusion

Finite Element Analysis is essential for modern pump design, especially when meeting the rigorous demands of API 610. Beyond just stress validation, FEA plays a critical role in the pump–piping interface, ensuring nozzle loads, stiffness, and casing integrity are well understood and managed.

By working closely with pipe stress engineers and sharing accurate stiffness data, pump designers can prevent costly rework, improve system reliability, and deliver equipment that stands the test of time. (For deeper reading on mesh and model fidelity in FEA workflows, see XCEED’s blog on Finite Element Analysis Convergence and Mesh Independence.)

Need FEA support or nozzle load analysis for your API 610 pump project? Our engineering team specializes in structural validation, stiffness evaluation, and piping integration. Reach out for a detailed consultation.