Understanding the Fundamentals of Finite Element Analysis

Finite Element Analysis (FEA) serves as a cornerstone in modern engineering, providing a powerful computational tool for predicting how products and structures will react to real-world forces, vibration, heat, and other physical effects. By breaking down complex structures into smaller, manageable elements, FEA allows engineers to simulate and analyze the behavior of materials and assemblies under various conditions. This process not only enhances design precision but also minimizes the risk of costly failures, contributing to safer and more reliable outcomes.

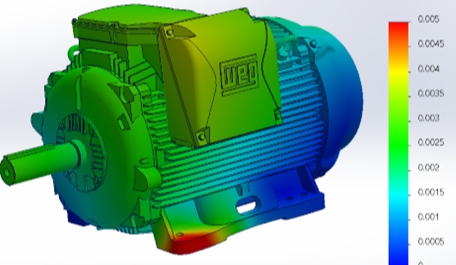

At its core, FEA operates by dividing a large, intricate object into a mesh of finite elements—tiny, interconnected units that collectively mimic the behavior of the original structure. Each element is analyzed separately, with the results combined to provide a comprehensive picture of how the overall design will perform. This approach enables engineers to visualize stress concentrations, deformation patterns, and potential weak points long before a prototype is ever built.

Key Advantages of FEA

- Enhanced Accuracy: Predicts a component’s real-world response with remarkable precision.

- Cost Efficiency: Reduces the need for extensive physical prototyping and material waste.

- Design Optimization: Facilitates iterative improvements by identifying and addressing vulnerabilities early in the process.

Grasping the fundamentals of FEA is crucial for anyone seeking to elevate their projects through advanced simulation and intelligent design decisions. This foundational knowledge sets the stage for meaningful collaboration with FEA specialists, ensuring your innovations stand up to both expectations and external demands.

Exploring the Benefits of Structural and Thermal Simulations

Harnessing the power of structural and thermal simulations transforms the approach to engineering challenges, providing a robust foundation for innovation and risk mitigation. By employing finite element analysis (FEA), engineers can delve deep into how materials and assemblies will behave under various loads, temperatures, and operating conditions—long before a prototype is manufactured. This predictive capability is invaluable for optimizing designs, reducing material costs, and ensuring end-product reliability.

Comprehensive Insight and Optimization

Structural simulations enable precise evaluation of stress, strain, and deformation within a component or system. This clarity empowers teams to identify weak points, reinforce critical areas, and streamline geometries for maximum strength-to-weight ratios. Whether designing aerospace structures, automotive components, or civil infrastructure, the ability to predict and address potential failures elevates safety and performance standards.

Thermal Analysis for Enhanced Performance

Thermal simulations go hand in hand with structural analysis, especially when products operate in fluctuating or extreme temperatures. By modeling heat transfer, engineers can predict temperature gradients, thermal expansion, and potential points of thermal fatigue. This insight guides the selection of appropriate materials, cooling strategies, and insulation techniques, ultimately extending product lifespan and preventing costly failures.

- Accelerate development cycles by minimizing physical prototyping

- Enhance accuracy in predicting real-world behavior

- Facilitate compliance with safety and industry standards

With these advantages, integrating structural and thermal simulations into your project workflow becomes not just a benefit, but a strategic necessity—laying the groundwork for informed engineering decisions and successful outcomes.

Key Advantages of Collaborating with a Simulation Specialist

Partnering with a finite element analysis (FEA) specialist brings a strategic edge to your projects, intertwining advanced technical insight with practical, real-world applications. The expertise of a simulation specialist goes far beyond routine calculations; it opens doors to innovative solutions and streamlined development processes that elevate the quality and performance of your products.

Expertise That Drives Precision

Simulation specialists possess a deep understanding of complex engineering principles and the latest simulation software. Their proficiency enables them to identify potential design flaws early, significantly reducing the risk of costly revisions down the line. By leveraging sophisticated FEA techniques, they can predict how materials and components will behave under various loading conditions, ensuring robustness and reliability from the outset.

Accelerated Development and Cost Savings

One of the standout benefits of collaborating with an FEA expert is the ability to accelerate your project timeline without sacrificing quality. Through virtual prototyping and rigorous scenario testing, simulation specialists help minimize the need for physical prototypes, leading to substantial savings in both time and resources. This efficiency not only speeds up the development cycle but also empowers your team to focus on innovation rather than troubleshooting.

Enhanced Decision-Making and Competitive Advantage

With comprehensive simulation data at your fingertips, you gain the clarity needed to make informed, data-driven decisions. This strategic insight translates into a competitive advantage, allowing you to bring superior, optimized products to market faster. In a landscape where precision and speed are paramount, the contribution of a skilled FEA specialist proves indispensable.

How a Finite Element Analysis Consultant Enhances Project Outcomes

In today’s fiercely competitive engineering landscape, precision and efficiency are paramount. Engaging a finite element analysis (FEA) consultant can dramatically transform the trajectory of your project, offering tangible advantages that extend far beyond conventional design and testing approaches.

Optimized Design Solutions

FEA consultants bring a wealth of specialized knowledge, allowing them to simulate complex physical phenomena with remarkable accuracy. By leveraging advanced simulation tools, they can pinpoint stress concentrations, predict failure modes, and optimize component geometries before any physical prototype is built. This proactive approach minimizes costly design iterations and accelerates the development cycle—ultimately shortening time to market.

Risk Mitigation and Enhanced Reliability

Early identification of potential weaknesses is a hallmark of effective FEA consulting. Through meticulous virtual testing, consultants uncover structural vulnerabilities and performance limitations under various loading scenarios. This foresight empowers project teams to make informed design modifications, thereby reducing the risk of unexpected failures and ensuring compliance with stringent industry standards.

Cost and Resource Efficiency

By harnessing the predictive power of finite element analysis, organizations can significantly reduce expenditure on materials and physical prototypes. Consultants help streamline resource allocation, ensuring that investments are directed toward the most impactful solutions. The result is a more robust, reliable, and cost-effective product.

Partnering with a skilled FEA specialist not only elevates the technical caliber of your project but also lays the foundation for innovation and long-term success.

Choosing the Right Specialist for Your Simulation Needs

Finding the perfect finite element analysis (FEA) specialist is paramount to the success of your engineering projects. The right expert brings not only technical proficiency but also a deep understanding of your industry’s unique challenges. Begin by assessing the specialist’s educational background and professional credentials—look for advanced degrees in mechanical or structural engineering and certifications in FEA software. However, technical knowledge alone is not enough. A seasoned specialist should have a proven track record of handling projects similar to yours, showcasing their ability to deliver robust simulation results under real-world constraints.

To ensure optimal collaboration, evaluate the candidate’s communication skills. Clear and concise reporting, as well as the ability to interpret complex simulation data, are critical. You want a specialist who listens to your objectives, explains methodologies in plain language, and integrates seamlessly with your team. Additionally, inquire about their familiarity with the latest simulation tools and their adaptability to rapidly evolving technologies.

Key Qualities to Look For

- Experience with Industry-Specific Projects: Prior work in your field enhances reliability and relevance.

- Problem-Solving Approach: Innovative thinking ensures challenges are addressed proactively.

- Software Proficiency: Mastery of leading FEA platforms such as ANSYS, Abaqus, or SolidWorks Simulation.

Choosing the right FEA specialist sets the stage for accurate simulations, informed decisions, and ultimately, the success of your projects. This careful selection process paves the way for seamless project execution and tangible results.