Custom Tool Solutions for Safety, Efficiency & Cost Savings

A tool is a device or handheld implement that aids in accomplishing a task. When tasks become complex, the tools available at your local hardware store may not be the best choice. XCEED works closely with you and your maintenance staff to develop ideal, custom tools to solve your toughest problems, eliminate occupational hazards, avoid re-work, increase worker efficiency, and reduce costs!

Demanding Applications

Nuclear power plants routinely undergo refueling outages during which the reactor is shut down, disassembled, and spent fuel replaced with new. However, shutting down for even a day can easily cost into the millions in lost revenues. As a result, a power plant’s economic viability hinges on minimizing outage duration and eliminating potential timetable delays.

Some workers must complete complex tasks in hazardous environments while wearing bulky and restrictive safety equipment. In the most extreme of cases, workers wear an encapsulated hazard suit with supplied air and limited sensory perception. In such equipment, even simple tasks can become troublesome for workers, leading to longer work times, increased uncertainty, and the potential for small mistakes to become big problems.

Custom tools are an excellent way to improve worker safety and efficiency while saving your bottom line in this dangerous and demanding working environment. During one scheduled reactor outage XCEED’s custom tools simultaneously saved our client significant manpower and critical-path schedule time.

Benefits of Custom Tools:

- Faster task completion: time is money!

- Reduced potential for costly mistakes: Eliminates inefficient field measurements by providing clear datums, hard-stops during installation

- Fewer workers needed in hazardous areas, reduced radiological dose

Design Requirements

In this nuclear application, scheduling and worker dose considerations demand successful first-time performance. Mistakes are unacceptable as re-work directly impacts critical-path schedule activities, radiation dose goals, and ultimately profit margins.

For our client success hinged on:

- Precision: Accuracy to place components within 0.0625” tolerance

- Quick Setup: Minimized setup time with little or no adjustment needed

- Reliability: Use of tools must be repeatable and dependable

- Handling: Minimal weight, rigging points to surmount situational handling obstacles

- Instruction: On-tool, easy to follow and understand

- Accelerated Timeline: Onsite within 4 weeks of initial contact, as required

- Cost: Achieves project goals while minimizing capital expense.

XCEED’s Engineered Solutions

Working with local suppliers, XCEED develops custom tools for the client by pairing modeling with ready-to-fabricate drawings. This is the foundation of our efficient integrated design process. Custom designs are modeled in SolidWorks, an industry-standard 3D CADD package. Using this platform XCEED demonstrated tool functionality, integrating client feedback before manufacture. Finite Element Analysis (FEA) is also available if required or requested.

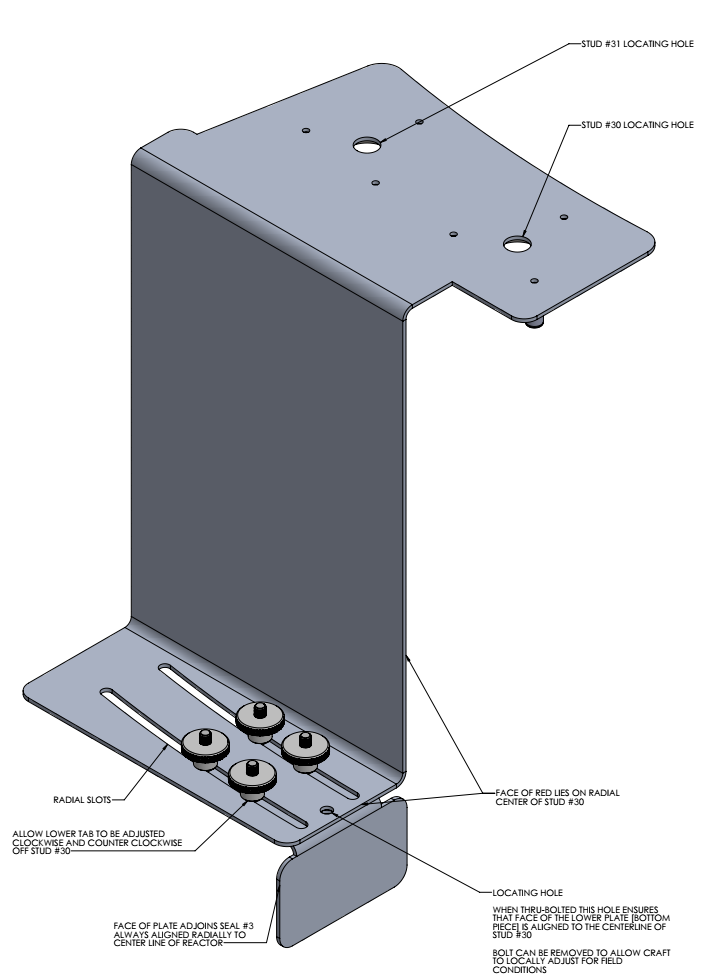

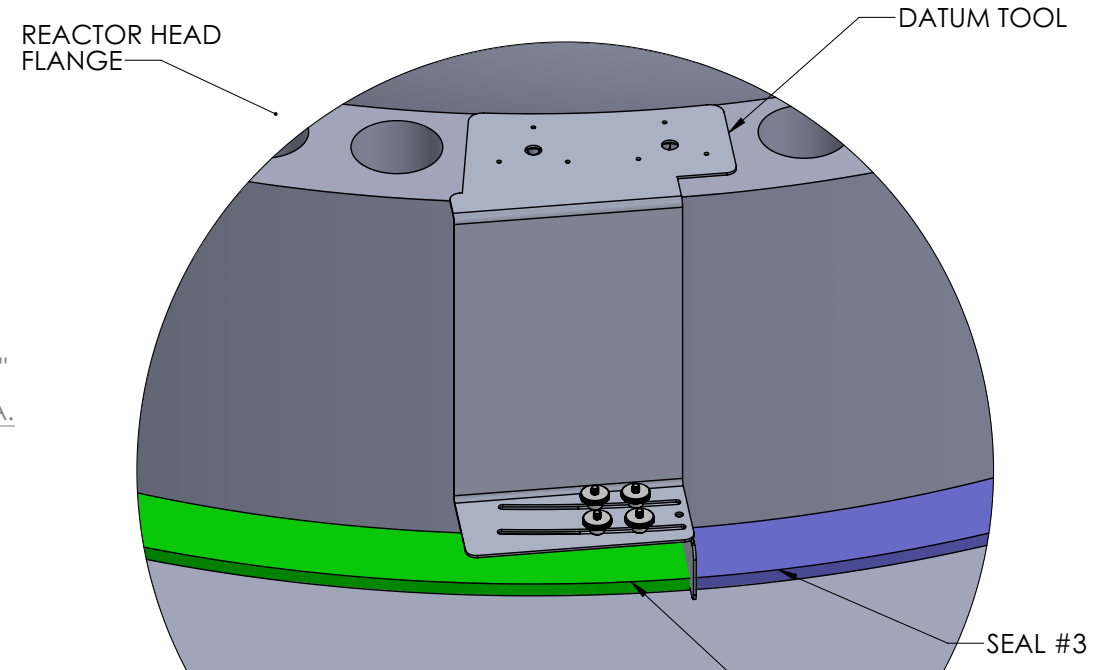

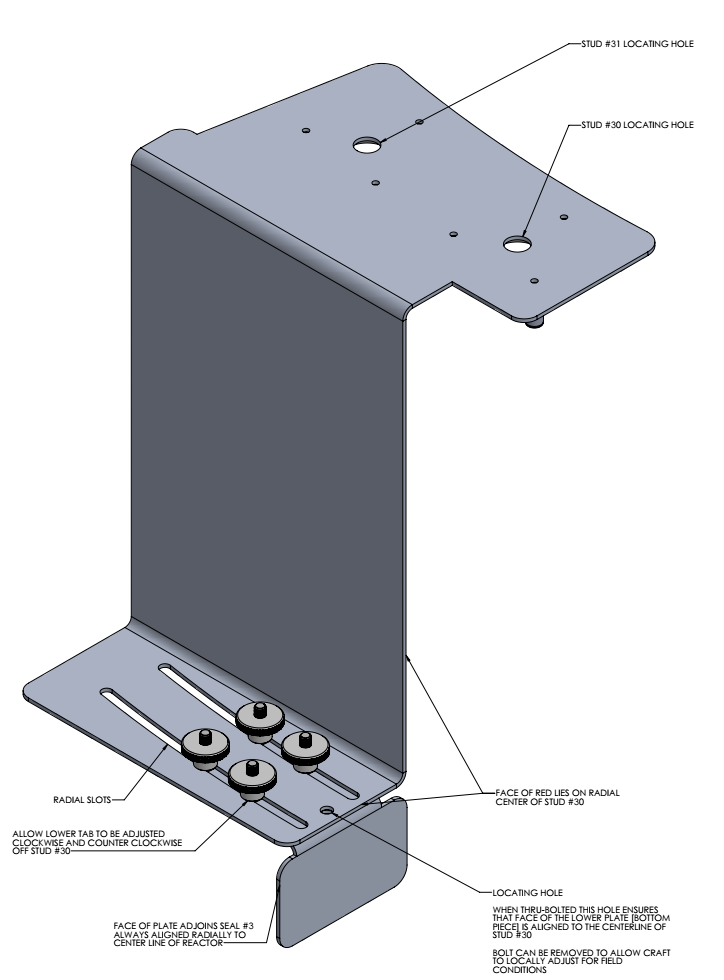

Reactor Cavity Seal Datum Tool

XCEED’s Reactor Cavity Seal Datum Tool assists workers with the initial placement of the 3-piece reactor cavity seal (shown in blue). Workers must align the seal with a consistent starting point around the flange as seal segments are installed. To achieve this, the tool interfaces with two existing flange stud holes and provides a hard-stop for crews to begin deployment of the seal.

Key Features:

- Precision: Laser-cut parts, Guaranteed accuracy of features to +/-0.005”

- Setup: Guide Dowels align tool in existing flange bolt holes

- Reliability: Self-centering, Precise, Consistent placement

- Instruction: Clear and Simple, Easy to see

- Handling: Balanced Lifting Eyes allow easy placement with overhead crane

The Cavity Seal Datum Tool saved our client an estimated 2 hours of critical path activities and reduced exposure to each worker by 100 mRem, roughly the equivalent of 10 chest x-rays.

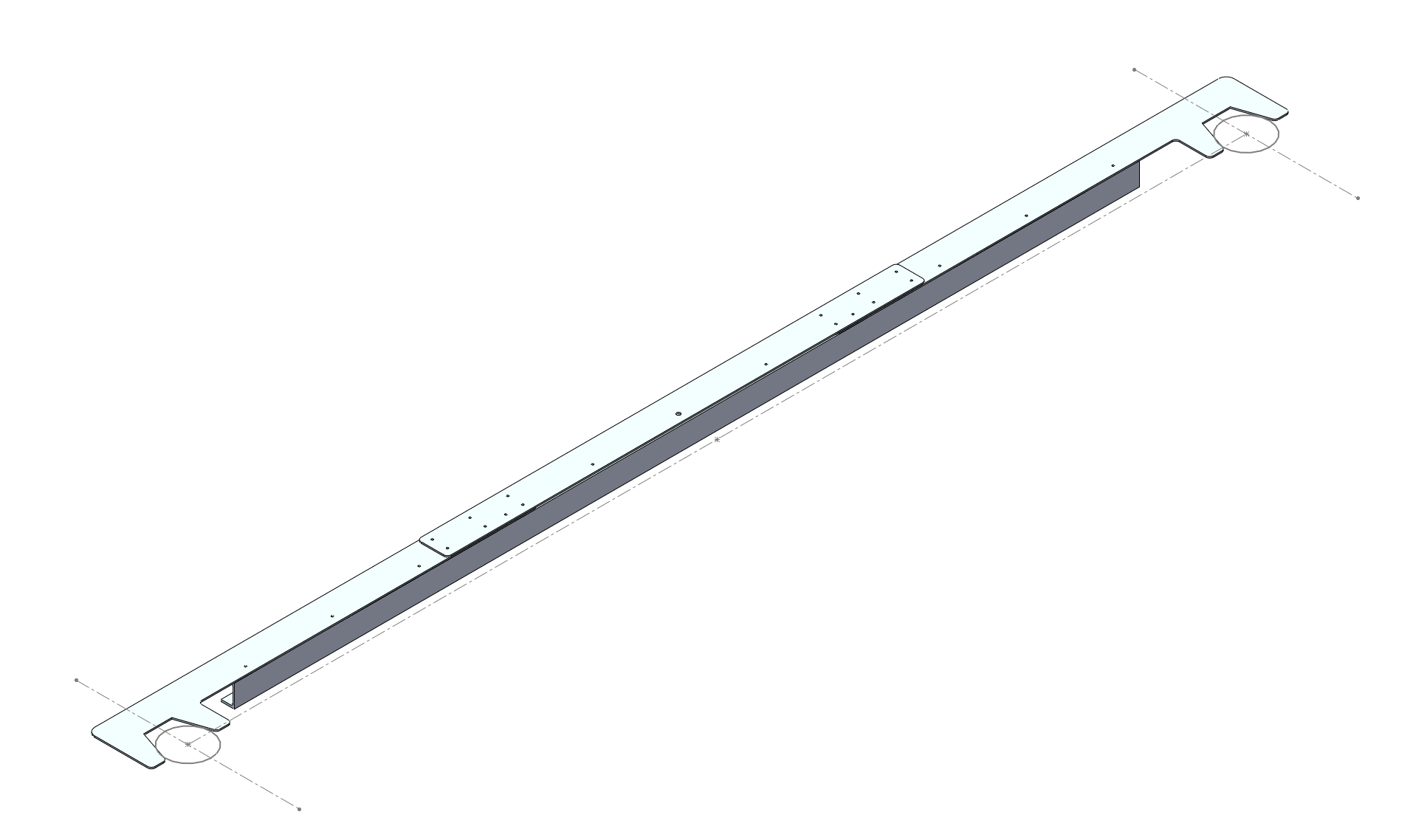

Lower Internals Guide Stud Jig

The Lower Internals Guide Stud Jig ensures two 6″ diameter alignment pins are spaced exactly 11′-8.304″ apart. Previously, workers used a tape measure for both placement and alignment of guide pins. Success was difficult to achieve considering the round surfaces of the pin, tight-tolerances and elevated working height. The Lower Internals Guide Stud Jig verifies center-to-center dimensions of the pins by using symmetrical tapered faces at each pin. An overhead crane carries the weight of the tool via balanced lifting eye, leaving workers’ hands free to align the pins.

Key Features:

- Precision: Laser-cut parts, guaranteed accuracy to +/-0.005”

- Setup: No-nonsense, no adjustment needed

- Reliability: Self-centering, precise placement

- Instruction: Clear and Simple, appropriately placed

- Handling: Balanced lifting eye, easy placement with overhead crane.

The Lower Internals Guide Stud Jig enabled the work detail to locate guide studs on first attempt in half the time and with half the number of workers: critical success!

Custom Tools for Mission-Critical Success

Each and every one of our custom-created tools enabled workers to finish tasks with peak efficiency and in record time. These custom tools are a few examples of ways we’ve helped clients with difficult situations. We’ve also worked on Industrial Structural Renovation, Cure In Place Pipe (CIPP) placement analysis, Structural Steel Code Compliance, Tornado Structural Safety Evaluation, various Finite Element Analysis (FEA) applications, and much more!

Call XCEED when it’s time for your next project! Our engineering staff are excited to work with you, creating custom solutions for even your most challenging problems, big or small. We’ll bring our expertise in the Nuclear, Power Generation and Utilities sectors and work with you to explore a variety of solutions.