XCEED Engineering Project Portfolio: Solutions & Case Studies

Home / Projects

Explore XCEED Engineering’s Latest Projects and Case Studies

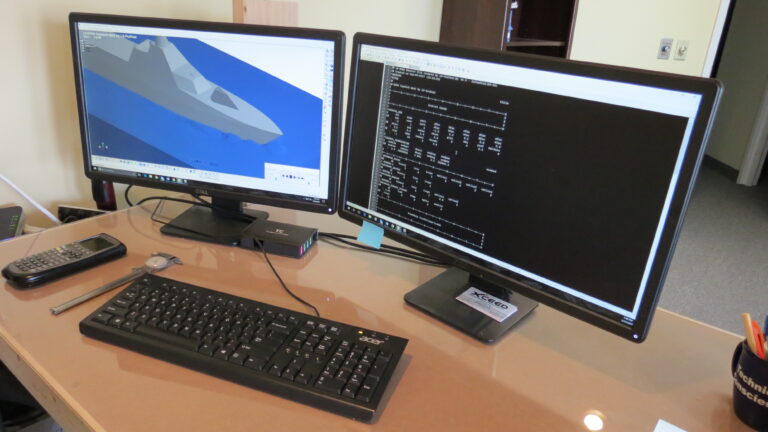

At XCEED Engineering and Consulting P.C., we know your projects demand more than just calculations and drawings—they demand solutions that work in the field. That’s why we focus on delivering results you can trust, combining advanced tools like finite element analysis (FEA) and pipe stress analysis with practical, fabrication-ready design.

When you partner with us, you’re not just getting engineers—you’re getting a team that understands your pressures as a Project Manager. We’ve helped clients like you cut project costs and timelines by up to 25% while still meeting tough deadlines and regulatory requirements. Our approach is built around your needs: smarter analysis, constructible design, and a commitment to making your job easier.

We’re small enough to stay responsive, but experienced enough to tackle the hardest problems in your industry. From delegated design packages to facility retrofits, we anticipate challenges before they hit the field, so you don’t deal with delays or rework.

Project Portfolio & Case Studies

When you manage high-stakes projects, you need more than a consultant—you need a partner who understands the pressure you’re under. That’s where we come in. Every project we share highlights how we’ve solved problems for PMs across industries—always with precision, speed, and efficiency. And because new challenges never stop, you’ll find this page continually updated with fresh examples of the results we deliver. With XCEED, you don’t just get engineering—you get peace of mind knowing your project is built to perform.

Modular Platform Design

A research institution required a modular, hand-assembled maintenance platform to service a component that is accessed only infrequently. The design challenge included the need for a large central opening and the ability to adapt to three specific elevation levels. Design: Taking into account standard maintenance practices, crane hook height limitations, and obstructions caused by nearby equipment, XCEED developed initial conceptual

Large Ballast Tank (LBT) Enhancements

Overview: The Large Ballast Tank (LBT) serves as a surge volume for off gas from a critical refrigeration cycle. The temperature of the outdoor tank is closely linked to the system pressure, and variations in temperature can significantly impact experimental results. HVAC Calculations: XCEED conducted detailed HVAC calculations for the outdoor tank to assess the necessary insulation and heat tracing

Double Wall Piping System for Deuterium Gas

Project Overview: XCEED developed, designed, and analyzed a double wall piping system specifically for the safe transport of deuterium gas. This system was crucial for ensuring the integrity and safety of the gas handling processes within the facility. Design and Routing: Compliance and Analysis: Outcome: The successful development and analysis of the double wall piping system for deuterium gas not

Helium Covergas System Enhancement [Blower Replacement]

Helium Covergas System Enhancement Overview: A research facility uses helium covergas to minimize contamination of the process fluid. The existing system, a vintage 1960s circulating blower system, was deemed outdated and inefficient. Investigation and Technology Selection: XCEED conducted a thorough evaluation of several modern blower/compressor technologies to replace the antiquated blower system. After careful consideration, a set of liquid ring

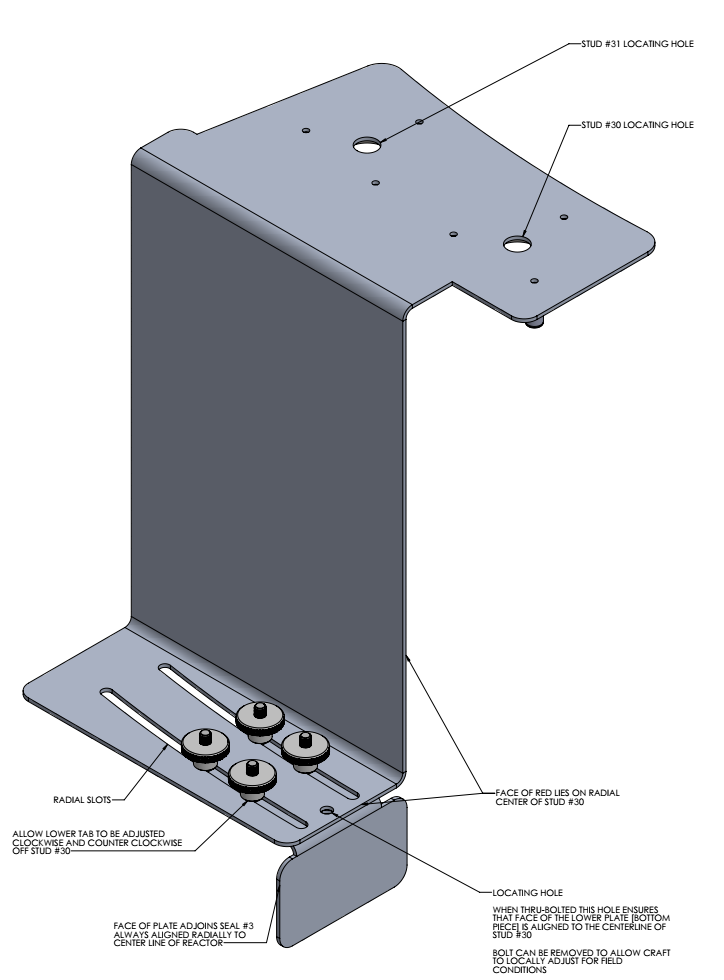

Custom Tool Design and Fabrication

Custom Tools A tool is a device or handheld implement that aids in accomplishing a task. When tasks become complex, the tools available at your local hardware store may not be the best choice. XCEED works closely with you and your maintenance staff to develop ideal, custom tools to solve your toughest problems, eliminate occupational hazards, avoid re-work, increase worker efficiency,

Preventing Fatigue Failure

Pumps and compressors vibrate. It’s a natural phenomena for anything that rotates or reciprocates, and it’s unavoidable. Normally, it’s not a problem. Until the vibrations hit resonance. When you have a pump or system operating at resonance, it can cause a fatigue failures. Recently, we found an example of this at a nuclear utility. They were having repeated fatigue failures

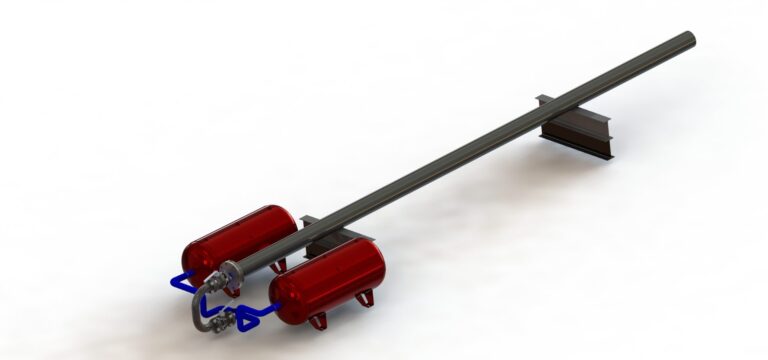

Articulating Solar Array

We were able to help our client save over $40,000 on the design and construction of an articulating solar array.

Condensate and Feedwater Upgrade

After an Extended Power Uprate (EPU), a power plant was having problems with Net Positive Suction Head (NPSH) on the Feedwater Pumps. They were worried about damaging the pump, but they also didn’t want to replace it. We helped them without changing the pump.

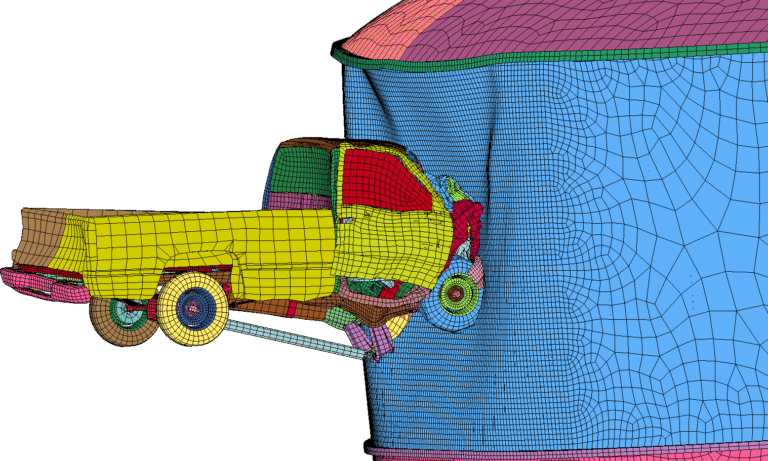

Ballistic Testing

Normally, we can test impacts using FEA. In this case, FEA wasn’t feasible, so we built a test stand to test missile impacts on block walls.

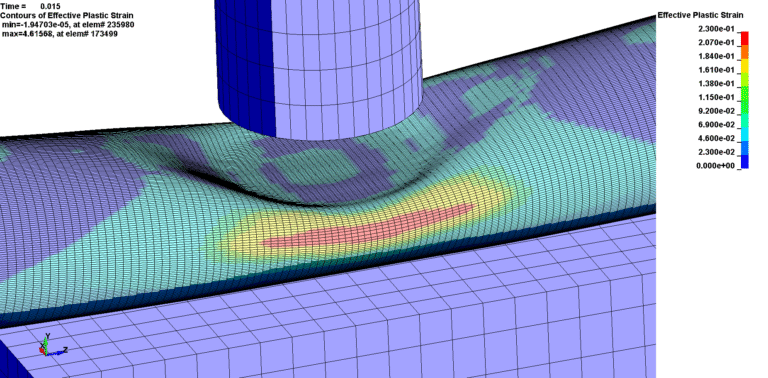

Tank Impact Evaluation

We found that API-650 tanks are more robust than most expect. The water in this tank absorbed 30% of the energy of a truck going 93 mph!

Trenchless Pipe Rehabilitation

Eventually, most steel rusts. And most buried pipes are made from steel. So what do you do when your buried pipe gets rusty? What if the pipe leaked?

Check Valve Failure Analysis

We diagnosed the failure of a nozzle check valve in an Auxiliary Feedwater System at a power plant. In summary: great valve, wrong application.

Fukushima FLEX Compliance Matrices

We have helped sites prepare for their TI-2515/191 inspections by using a tool we call the Compliance Matrix. Give us a call for more information.

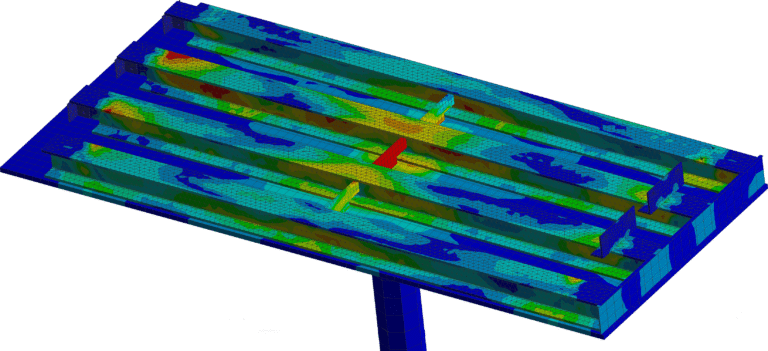

Tornado Missile Barriers

A nuclear plant found that they needed to protect pipes from wind driven missiles. We designed a barrier system for them using 3D modeling and FEA.

RCP Seal Leakoff

Using FEA and hand calculations, we were able to help a nuclear utility evaluate RCP Seal Leakoff pipes and components for high temperature and pressure.

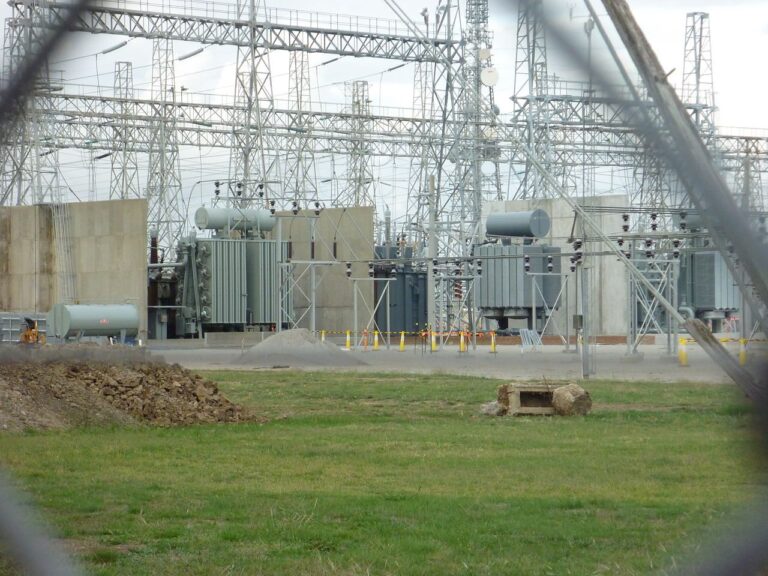

Transformer Foundation Design

We worked with a local utility to help design a foundation for a transformer. The design included the spill basin for transformer oil.

Flood Penetration Qualification

We developed a testing plan to test seals and determine their water resistance. A test rig was designed which put a static head on the sample flood seals.

Missile Barrier Design Review

We worked with a nuclear plant to optimize a shear wall design. The optimized design reduced the amount of rebar by about 30%.

Steam Pipe Integrity Evaluation

Tornado generated missiles can wreak havoc, especially on a nuclear power plant. We helped one site design and optimize a protection system.

Whether you’re seeking a fresh approach to a long-standing challenge, want to streamline your next project, or simply appreciate honest, field-proven expertise, we’re here to help. Reach out, ask the tough questions, and let’s find a better way forward—together.

XCEED Engineering and Consulting, P.C.—Redefining the Limits of Engineering.

We don’t just design solutions—we make sure they work in the real world.